The process

The sugar that we eat in Australia comes from a plant – sugarcane. In the hot and sunny climate of coastal Queensland and northern New South Wales with plenty of rain water, it grows to be more than two metres tall.

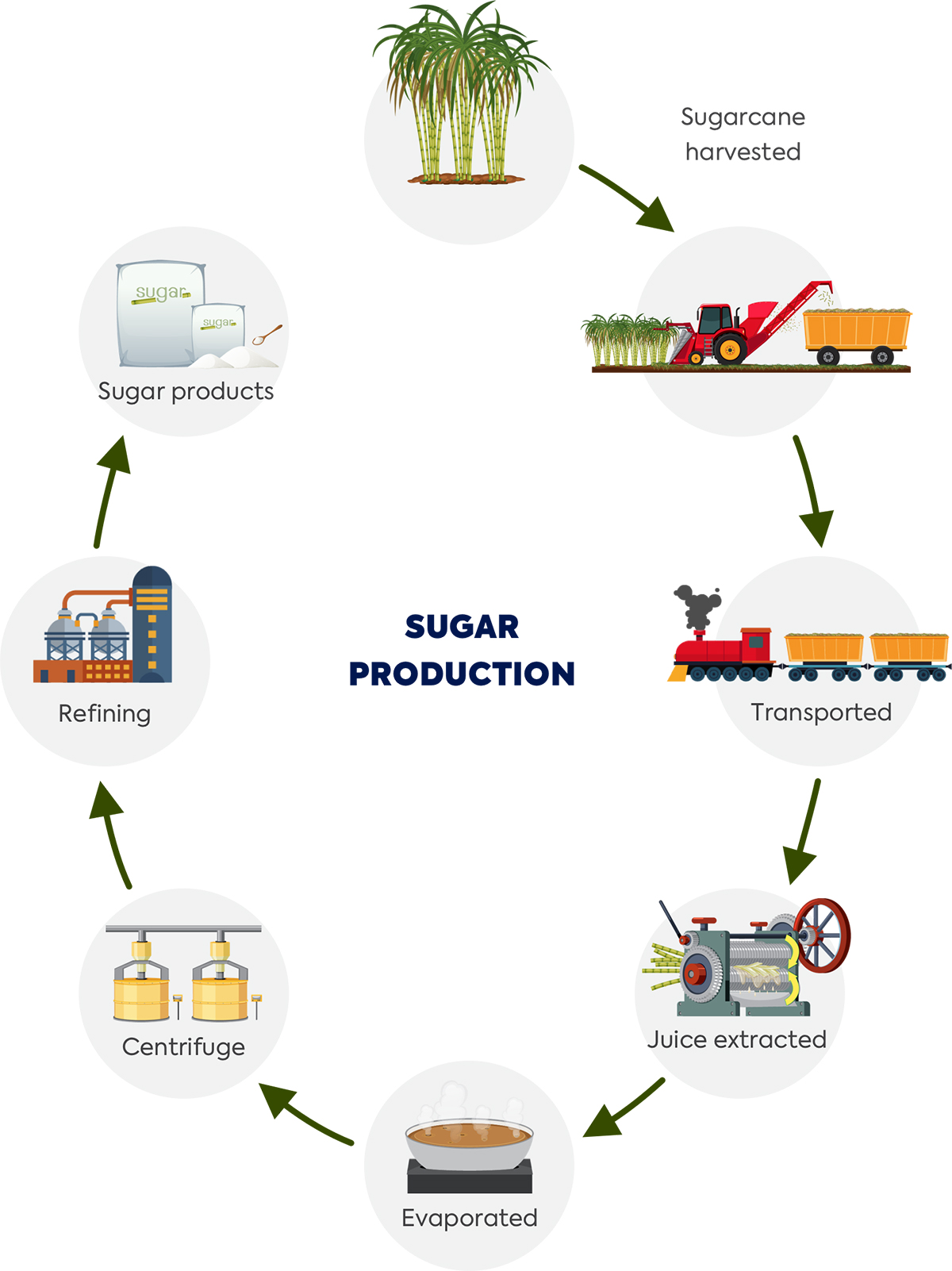

Sugarcane is harvested between June and December. Cane fires used to be common, but nowadays the leaves are chopped up and left as mulch to nourish the soil and the next crop. Because it’s a giant grass, sugarcane is cut down and regrown from its root ball (called a stool) for many years before it needs to be re-planted.

Once cut, the pieces of cane are sent as quickly as possible by road or rail to a sugar mill where they are shredded and crushed to separate the sweet juice from the fibrous stalk, which is called bagasse. The juice is then filtered and heated to remove the water and any impurities. The dark brown liquid that’s extracted in this process is called molasses. Finally, the juice is dried into crystals.

Raw sugar crystals are kept dry and stored in big sheds, ready to be exported by ship or sold to one of Australia’s four sugar refineries. Refineries make the raw sugar fit for human consumption by melting it and then sterilising it using UV light before spinning it in huge drying centrifuges. It’s then packaged up for sale.

To find out more about sugar see What is sugar?

The sugar industry is always looking for ways to minimise waste and the bagasse provides an ideal fuel to provide steam, heat and electricity from the sugar mill’s boiler. As only half of the electricity generated is needed to produce sugar, the other 50% is exported to the grid and used to power over 139,000 regional households.

The many different types of sugar on sale (dark brown, raw, caster and demerara) are determined at this point by how long its spun and how much of the molasses is included.The finished sugar is then ready to be packaged up to be sold in a supermarket or to food and drink manufacturers.